Some technical standards might require bigger engines than necessary for an operation.

I want to share with you the phenomenon of “the bigger, the better,” as personally experienced by me. When I grew up, my parents, three children and our grandmother shared a home of 1400 square feet with three bedrooms. The three children shared one bedroom — not a lot of privacy, but we all grew up well. One became a brigadier general, one became a doctor, and one became a pilot. None of us can recall being crowded or restricted.

When I got married in the 80s, we bought a home of 2400 square feet with three bedrooms, which looked huge at the time. By the time we had children, we moved to a 5000-square-foot home with five bedrooms and four bathrooms and a pool that I may use only five to six times a year. We live in Toronto. How did we end up in this big place? I think it is what we call peer pressure: buying and spending on things we don’t really need or use most of the time.

How is this story related to GPU technology? Let me tell you.

We manufacture GPU products according to demands expressed through purchase orders issued by end users. We develop and introduce new products, mainly to fulfill the customers’ requirements.

Normally, customer requirements will originate with the specification published by aircraft manufacturers. From there, an evaluation of other local requirements such as aircraft mix on the apron, weather, available facilities, etc., will be taken into account. On the other hand, GPU manufacturers will offer products that are designed and built to meet various standards, mostly related to the quality and specifications of the electrical output, safety requirements for structure, operations and the requirements related to pollution factors of noise, emission, and hazardous materials. Up to this point, it all makes good sense from every point of view.

When these processes are implemented through various publications of specifications and in trying to cover for every possibility — as remote as it may be — we end up with “the bigger, the better” syndrome. The details are buried in the “small print” and in certain situations, as described further below, it brings about legitimate questions of cross purpose.

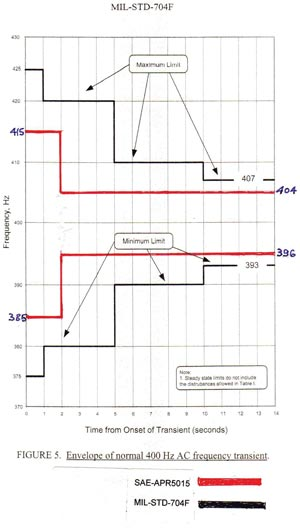

Take, for example, the standards associated with “frequency stability,” which are designed to ensure the supply of current frequency with minimum fluctuations. To this day, MIL-STD-704E still provides the basic platform for GPU design for the frequency fluctuations during transient load episode (going either up or down); i.e., maximum destabilized frequency fluctuation of ± 25Hz at the onset of the transient episode, decreasing to ± 7Hz within 10 seconds.

Technology advancements in the electrical functions of newer aircraft drives the demand for higher accuracy of the current supply, so we aspire to further narrow the regulation of frequency fluctuations to a maximum of ± 15Hz at the onset of the transient episode, decreasing to ± 4Hz within two seconds. as per SAE publication APR5015. So far so good.

However, in the same document, APR5015, the above improvement in frequency tolerances is also accompanied by the recommendation for increasing the load envelope of controlled frequency regulation. In fact, the publication recommends for 100-percent load envelope, i.e., the requirement for frequency regulation is to perform during transient loads equal to the full rated capacity of the unit. Just to make this clear, it means that a GPU rated at 90 kva is required to maintain its frequency regulated at the above-mentioned rate during a load transient from 100-percent power to 0-percent power and back to 100-percent power. Here is where I question the wisdom and the practical basis for the APR5015 demand.

An airline analogy for comparison would be an FAA standard requiring the airlines to widen all seats in the aircraft by 33 percent to accommodate heavy set persons that may or may not come on the flight.

Since that same standard, SAE-APR5015, is now recommending that GPUs should not be used to clear aircraft electrical faults and we have done away with the requirement for 150-percent overload capability, I can’t imagine any practical occurrences where a GPU will be under a full load and then lose it and then immediately regain it; or alternatively, where a GPU will be connected to an aircraft that will instantaneously demand a full load from the GPU.

The reality is that the operator/user is now buying GPUs with engines that are bigger by some 33 percent than before, just to be able to comply with this requirement.

Example? The manufacturer of a GPU rated for 120 kva will have to use an engine that will provide at least 170 kva (215 hp) in order to accommodate sufficient margining for full compliance. If you are curious, this is how it looks for some other GPU sizes:

- Rated: 180 kva; engine required: 325 hp (256 kva)

- Rated: 140 kva; engine required: 276 hp (217 kva)

- Rated: 90 kva; engine required: 177 hp (139 kva)

Who is paying? Mainly, the airlines. In addition, the environment; we all pay.

About the author: Arie Tall has held positions as an airline pilot, chief pilot, director of flight operations, and airline VP. He is the business owner of an airline, ground handling company and has taken on the latest challenge of designing and manufacturing GPUs under the name Jetall GPU.

About the author: Arie Tall has held positions as an airline pilot, chief pilot, director of flight operations, and airline VP. He is the business owner of an airline, ground handling company and has taken on the latest challenge of designing and manufacturing GPUs under the name Jetall GPU.

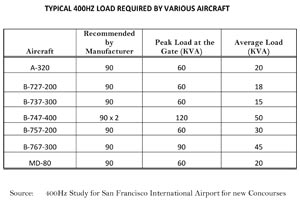

Illustration of the margining provided by the manufacturer’s recommendations vs. the average and peak of consumption experienced at the gate.

The imposed hand drawing (in red) of the SAE-APR5015 advisory, illustrating the severity of the gap, when compared to the latest version MIL-STD-704F.