When it comes to the aviation industry, efficiency and reliability are paramount. Ground support equipment (GSE) is crucial in ensuring seamless airport operations. Proper maintenance is vital to maximizing performance and longevity for businesses leasing GSE. In this blog post, we’ll explore valuable tips to help you keep your leased GSE in top-notch condition, ensuring operational excellence and minimizing downtime.

When it comes to the aviation industry, efficiency and reliability are paramount. Ground support equipment (GSE) is crucial in ensuring seamless airport operations. Proper maintenance is vital to maximizing performance and longevity for businesses leasing GSE. In this blog post, we’ll explore valuable tips to help you keep your leased GSE in top-notch condition, ensuring operational excellence and minimizing downtime.

BLOG

Future Trends in Ground Support Equipment- Ensuring aircraft’s smooth and safe operations

As the aviation industry continues its upward trajectory, the need for streamlined efficiency and advanced Ground Support Equipment (GSE) has remained the same. GSE plays a crucial role in ensuring aircraft’s smooth and safe operations on the ground. In this blog post, we’ll explore the future trends in Ground Support Equipment, envisioning a horizon where GSE-R-US leads innovation and reliability.

As the aviation industry continues its upward trajectory, the need for streamlined efficiency and advanced Ground Support Equipment (GSE) has remained the same. GSE plays a crucial role in ensuring aircraft’s smooth and safe operations on the ground. In this blog post, we’ll explore the future trends in Ground Support Equipment, envisioning a horizon where GSE-R-US leads innovation and reliability.

Smart and Connected GSE: The future of ground support equipment lies in its ability to connect seamlessly with other components of airport operations. Smart GSE, equipped with IoT (Internet of Things) technology, can communicate real-time data, enabling predictive maintenance and optimizing operational efficiency. Imagine a scenario where a baggage loader can anticipate maintenance needs before a breakdown occurs, preventing costly delays and ensuring a smoother passenger experience.

Electric and Sustainable GSE: In line with the global push towards sustainability, the aviation industry is witnessing a shift towards electric and environmentally friendly solutions. Electric GSE reduces carbon emissions and lowers operational costs through decreased fuel consumption and maintenance requirements. GSE-R-US is at the forefront of this eco-friendly revolution, offering a range of electric-powered tugs, baggage tractors, and ground-power units.

Autonomous GSE Operations: The future of ground support equipment is independent. Imagine robotic tugs navigating the tarmac precisely guided by advanced sensors and AI algorithms. Autonomous GSE operations promise increased efficiency, reduced human errors, and enhanced safety. GSE-R-US invests in cutting-edge technology to develop autonomous baggage loaders, fuel trucks, and pushback tugs, revolutionizing ground handling procedures.

Augmented Reality (AR) for Maintenance and Training: AR technology is set to transform GSE maintenance and training procedures. GSE-R-US recognizes the potential of AR in providing technicians with real-time, hands-free access to maintenance procedures and schematics, reducing downtime and improving overall efficiency. Additionally, AR can be employed in training programs, offering immersive and interactive simulations for GSE operators, ensuring a skilled and confident workforce.

Data Analytics for Performance Optimization: The future of GSE is data-driven. GSE-R-US harnesses the power of big data analytics to monitor equipment performance, fuel consumption, and maintenance patterns. Through meticulous analysis of extensive data sets, GSE operators gain valuable insights to refine operations, enhance equipment longevity, and minimize operational expenses. The integration of predictive analytics is instrumental in preemptively identifying issues, enabling a proactive maintenance approach to mitigate potential problems before they escalate.

As GSE-R-US propels into the future, it is clear that the landscape of ground support equipment is evolving rapidly. Integrating innovative technology, sustainability initiatives, autonomy, augmented reality, and data analytics is shaping the next generation of GSE. By staying at the forefront of these trends, GSE-R-US ensures the efficiency and reliability of ground operations and contributes to a greener and more sustainable aviation industry. As we look ahead, the horizon for GSE-R-US is filled with innovation, connectivity, and a commitment to shaping the future of ground support equipment.

Recent Innovations in Ground Support Equipment

Welcome to GSE-R-US, your trusted source for all things related to Ground Support Equipment (GSE). Today, we’re excited to dive into the dynamic world of GSE innovation. The aviation industry is constantly evolving, and the equipment used to support it on the ground is no exception. In this blog, we’ll explore recent innovations in GSE that are shaping the future of airport operations and sustainability.

Welcome to GSE-R-US, your trusted source for all things related to Ground Support Equipment (GSE). Today, we’re excited to dive into the dynamic world of GSE innovation. The aviation industry is constantly evolving, and the equipment used to support it on the ground is no exception. In this blog, we’ll explore recent innovations in GSE that are shaping the future of airport operations and sustainability.

Electric GSE and Sustainable Power Sources

years is the transition towards electric GSE. Electric baggage tractors, aircraft tugs, and GPUs (Ground Power Units) are becoming increasingly popular due to their reduced carbon footprint and lower operational costs. The shift towards sustainable power sources, such as solar and battery technology, is making GSE more eco-friendly than ever.Smart GSE Management

The aviation industry is embracing the power of data analytics and smart technology to enhance GSE management. Airport operators are implementing systems that track GSE usage, maintenance schedules, and fuel consumption in real-time. This data-driven approach helps optimize equipment deployment, reduce downtime, and improve efficiency.Autonomous GSE

The concept of autonomous ground support equipment is no longer a sci-fi fantasy. Autonomous baggage carts, catering trucks, and even pushback tractors are being developed and tested. These innovations can reduce human error, improve safety, and enhance efficiency on the tarmac.Sustainable Fuels and Hybrid GSE

To further reduce the carbon footprint of GSE, the aviation industry is exploring sustainable fuel options for equipment like aircraft tugs and fuel trucks. Additionally, hybrid GSE, which combines electric and conventional power sources, is gaining traction. These innovations are not only environmentally responsible but also cost-effective.GSE Connectivity and Remote Monitoring

GSE manufacturers are integrating connectivity features into their equipment. It allows for remote monitoring, diagnostics, and software updates. In case of a malfunction or maintenance requirement, GSE operators can be alerted promptly, reducing downtime and ensuring safer operations.Lightweight Materials and Ergonomic Design

Innovations in materials and design have led to lighter GSE with enhanced ergonomic features. Lightweight GSE is more straightforward to maneuver, reducing operator fatigue and improving overall efficiency on the ground. As the aviation industry strives for greater sustainability and efficiency, GSE continues to evolve to meet these demands. These innovations not only benefit airports and airlines but also contribute to a more environmentally responsible and passenger-friendly travel experience. In conclusion, Ground Support Equipment is experiencing a fascinating transformation. From electric and autonomous GSE to sustainable power sources and smart management, the aviation industry is making impressive strides toward more efficient and eco-friendly ground operations. Stay tuned to GSE-R-US for the latest updates on these innovations and more as we continue to explore the future of GSE.GPUs: The Bigger, the Better?

Some technical standards might require bigger engines than necessary for an operation.

I want to share with you the phenomenon of “the bigger, the better,” as personally experienced by me. When I grew up, my parents, three children and our grandmother shared a home of 1400 square feet with three bedrooms. The three children shared one bedroom — not a lot of privacy, but we all grew up well. One became a brigadier general, one became a doctor, and one became a pilot. None of us can recall being crowded or restricted.

When I got married in the 80s, we bought a home of 2400 square feet with three bedrooms, which looked huge at the time. By the time we had children, we moved to a 5000-square-foot home with five bedrooms and four bathrooms and a pool that I may use only five to six times a year. We live in Toronto. How did we end up in this big place? I think it is what we call peer pressure: buying and spending on things we don’t really need or use most of the time.

How is this story related to GPU technology? Let me tell you.

We manufacture GPU products according to demands expressed through purchase orders issued by end users. We develop and introduce new products, mainly to fulfill the customers’ requirements.

Normally, customer requirements will originate with the specification published by aircraft manufacturers. From there, an evaluation of other local requirements such as aircraft mix on the apron, weather, available facilities, etc., will be taken into account. On the other hand, GPU manufacturers will offer products that are designed and built to meet various standards, mostly related to the quality and specifications of the electrical output, safety requirements for structure, operations and the requirements related to pollution factors of noise, emission, and hazardous materials. Up to this point, it all makes good sense from every point of view.

When these processes are implemented through various publications of specifications and in trying to cover for every possibility — as remote as it may be — we end up with “the bigger, the better” syndrome. The details are buried in the “small print” and in certain situations, as described further below, it brings about legitimate questions of cross purpose.

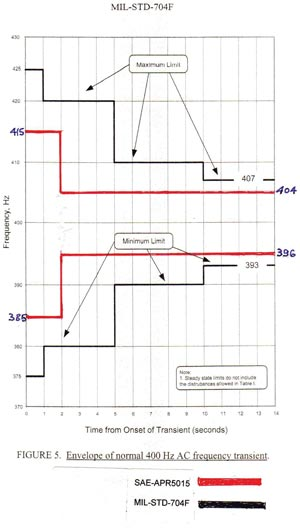

Take, for example, the standards associated with “frequency stability,” which are designed to ensure the supply of current frequency with minimum fluctuations. To this day, MIL-STD-704E still provides the basic platform for GPU design for the frequency fluctuations during transient load episode (going either up or down); i.e., maximum destabilized frequency fluctuation of ± 25Hz at the onset of the transient episode, decreasing to ± 7Hz within 10 seconds.

Technology advancements in the electrical functions of newer aircraft drives the demand for higher accuracy of the current supply, so we aspire to further narrow the regulation of frequency fluctuations to a maximum of ± 15Hz at the onset of the transient episode, decreasing to ± 4Hz within two seconds. as per SAE publication APR5015. So far so good.

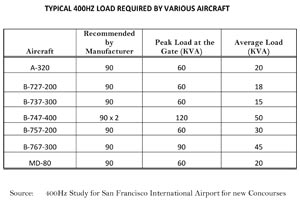

However, in the same document, APR5015, the above improvement in frequency tolerances is also accompanied by the recommendation for increasing the load envelope of controlled frequency regulation. In fact, the publication recommends for 100-percent load envelope, i.e., the requirement for frequency regulation is to perform during transient loads equal to the full rated capacity of the unit. Just to make this clear, it means that a GPU rated at 90 kva is required to maintain its frequency regulated at the above-mentioned rate during a load transient from 100-percent power to 0-percent power and back to 100-percent power. Here is where I question the wisdom and the practical basis for the APR5015 demand.

An airline analogy for comparison would be an FAA standard requiring the airlines to widen all seats in the aircraft by 33 percent to accommodate heavy set persons that may or may not come on the flight.

Since that same standard, SAE-APR5015, is now recommending that GPUs should not be used to clear aircraft electrical faults and we have done away with the requirement for 150-percent overload capability, I can’t imagine any practical occurrences where a GPU will be under a full load and then lose it and then immediately regain it; or alternatively, where a GPU will be connected to an aircraft that will instantaneously demand a full load from the GPU.

The reality is that the operator/user is now buying GPUs with engines that are bigger by some 33 percent than before, just to be able to comply with this requirement.

Example? The manufacturer of a GPU rated for 120 kva will have to use an engine that will provide at least 170 kva (215 hp) in order to accommodate sufficient margining for full compliance. If you are curious, this is how it looks for some other GPU sizes:

- Rated: 180 kva; engine required: 325 hp (256 kva)

- Rated: 140 kva; engine required: 276 hp (217 kva)

- Rated: 90 kva; engine required: 177 hp (139 kva)

Who is paying? Mainly, the airlines. In addition, the environment; we all pay.

About the author: Arie Tall has held positions as an airline pilot, chief pilot, director of flight operations, and airline VP. He is the business owner of an airline, ground handling company and has taken on the latest challenge of designing and manufacturing GPUs under the name Jetall GPU.

About the author: Arie Tall has held positions as an airline pilot, chief pilot, director of flight operations, and airline VP. He is the business owner of an airline, ground handling company and has taken on the latest challenge of designing and manufacturing GPUs under the name Jetall GPU.

Illustration of the margining provided by the manufacturer’s recommendations vs. the average and peak of consumption experienced at the gate.

The imposed hand drawing (in red) of the SAE-APR5015 advisory, illustrating the severity of the gap, when compared to the latest version MIL-STD-704F.

Ground Power Units (GPUs) in Aviation: Powering Up for Success

Introduction

In the world of aviation, where efficiency and safety are paramount, Ground Power Units (GPUs) play a crucial role in ensuring the smooth operation of aircraft on the ground. GPUs are indispensable tools that provide electrical power to aircraft while they are parked at the gate or in maintenance areas. This blog post delves into the significance of GPUs, their working principles, types, benefits, and their role in modern aviation.

Understanding Ground Power Units

Ground Power Units, often referred to as GPU or external power supplies, are mobile or stationary devices that supply electrical power to aircraft when their engines are not running. This is essential for a variety of purposes, including pre-flight checks, maintenance, and passenger comfort. GPUs are designed to mimic the electrical power provided by an aircraft’s own engines, ensuring uninterrupted operation of onboard systems even when the engines are turned off.

Working Principles of GPUs

GPUs operate by connecting to the aircraft’s power receptacle, usually located near the nose or wing. They provide a stable and controlled supply of electrical power to the aircraft’s electrical systems, avionics, lighting, air conditioning, and other essential equipment. This allows for critical systems to remain active without draining the aircraft’s battery or using its APU (Auxiliary Power Unit).

Types of Ground Power Units

Mobile GPUs: These are self-contained units mounted on wheels, making them easily transportable to different aircraft on the tarmac. They are commonly used at airports with varying aircraft types and sizes.

Fixed GPUs: Stationary units installed at specific gates or maintenance areas. These GPUs are suitable for airports with a consistent fleet of aircraft.

Frequency Converters: In addition to providing electrical power, some GPUs also convert the power frequency to match the aircraft’s requirements, ensuring compatibility between the GPU and the aircraft.

Benefits of Using GPUs:

Fuel Savings: By using external power instead of running onboard engines or the APU, airlines can save on fuel costs and reduce emissions.

Reduced Engine Wear: GPUs help extend the life of aircraft engines by minimizing unnecessary engine starts and stops.

Noise Reduction: Keeping engines off during ground operations contributes to a quieter airport environment for passengers and surrounding communities.

Maintenance Efficiency: GPUs provide power for maintenance tasks, enabling technicians to work on the aircraft’s systems without relying on internal power sources.

Passenger Comfort: While waiting at the gate, passengers can enjoy a comfortable cabin environment with air conditioning, lighting, and entertainment systems powered by the GPU.

The Role of GPUs in Modern Aviation

In an era of heightened environmental awareness and cost efficiency, GPUs are indispensable tools that align with the aviation industry’s evolving needs. Airlines are increasingly adopting green practices, and using GPUs to reduce the carbon footprint of ground operations is a significant step in that direction. Furthermore, GPUs contribute to operational efficiency by reducing turnaround times, allowing aircraft to get back in the air sooner.

Conclusion

Ground Power Units are unsung heroes of aviation, quietly ensuring that aircraft remain operational and efficient while on the ground. Their ability to provide essential electrical power not only enhances aircraft maintenance and operations but also contributes to a more sustainable and environmentally friendly aviation industry. As airports and airlines continue to prioritize efficiency and eco-friendliness, the role of GPUs in aviation is poised to become even more vital in the years to come.

Air Start Units (ASUs) in Aviation: Breathing Life into Jet Engines

Introduction

In the fast-paced world of aviation, where every minute counts, Air Start Units (ASUs) play a critical role in powering up jet engines. ASUs are essential ground support equipment used to initiate the rotation of jet engines, enabling aircraft to start their engines without the need for onboard power. In this blog post, we’ll explore the significance of ASUs, their functioning, types, and their role in ensuring smooth operations at airports worldwide.

Understanding Air Start Units

Air Start Units, commonly referred to as ASUs, are mobile devices designed to provide compressed air to aircraft engines during the starting process. These units are particularly crucial for larger aircraft, such as commercial airliners, which require a significant amount of air flow to initiate the engine’s rotation and start the combustion process.

How Air Start Units Work

ASUs operate by delivering high-pressure, pre-compressed air directly into the aircraft’s engine starter. This air serves as the driving force that turns the engine’s core components, eventually leading to ignition and the self-sustained running of the engine. ASUs ensure that engines start up reliably and safely, even in challenging weather conditions.

Types of Air Start Units

Mobile ASUs: These units are mounted on trucks, making them easily transportable around the airport. Mobile ASUs are versatile and can be deployed to various aircraft as needed.

Cart-Mounted ASUs: These units are more compact and are often found on smaller airports or used for regional aircraft. They can be easily moved around by airport personnel.

Stationary ASUs: Larger airports or those with consistent aircraft types may have fixed ASUs located strategically at different bridge gates or maintenance areas.